「Deep Learning」

Machine Learning Advanced Service

"Deep Learning" advanced machine learning service

In-depth physical examination to understand the health status of old solar power plants

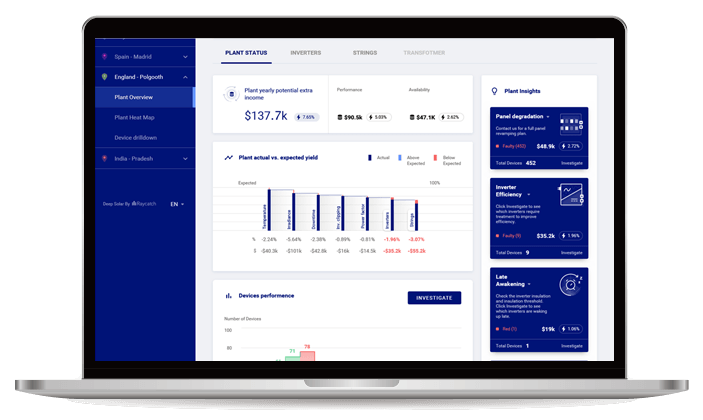

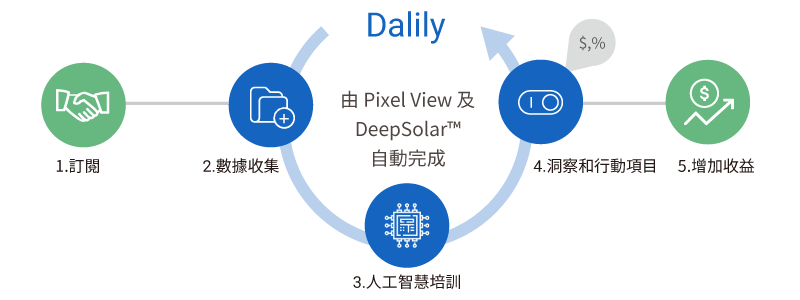

Shengqi cooperated with an Israeli artificial intelligence software company to launch the "Deep Learning" advanced machine learning service. Just install the Pixel View monitoring system, you can apply for an upgrade and use the existing power plant data for data analysis. Through the extremely complex algorithm, Interpret all index data of solar energy and analyze the reasons for the decline in power generation efficiency, deeply study the power generation behavior of power plants in the past year, and analyze 20 reasons for the decline in power generation indicators:

In-depth physical examination to understand the health status of old solar power plants

Shengqi cooperated with an Israeli artificial intelligence software company to launch the "Deep Learning" advanced machine learning service. Just install the Pixel View monitoring system, you can apply for an upgrade and use the existing power plant data for data analysis. Through the extremely complex algorithm, Interpret all index data of solar energy and analyze the reasons for the decline in power generation efficiency, deeply study the power generation behavior of power plants in the past year, and analyze 20 reasons for the decline in power generation indicators:

Major Analysis Items

Including: Converter Clipping, Data Collection Integrity, Voltage and Frequency Deviation, Module Temperature Coefficient Abnormal, MPPT/Inverter Efficiency Abnormal, MPPT Accuracy, Disconnected Serial, Inverter Conversion Efficiency Poor, Inverter Failure or Due to factors such as getting up late, environmental sensor failures, etc., a quantifiable renovation and maintenance plan is proposed, and preventive abnormal maintenance and corrective measures are carried out, which can increase the average power generation of old power plants by 3-8% and reduce O&M costs by 10-12%.

| frequency deviation | Converter data integrity | Inverter wakes up late |

|---|---|---|

| Abnormal temperature coefficient | Converter Clipping | Converter failure |

| Device disconnection | Voltage deviation | Abnormal power factor |

| Solar Meter Data Integrity | Tandem power generation performance | Abnormal temperature alarm |

| Environmental sensor failure | Tandem Generation Data Integrity | Converter/AC meter power generation ratio |

| Environmental Sensor Data Consistency | MPPT exception | Transformer is inefficient |

| Solar module clean/dirty | Converter efficiency below specification | Transformer temperature is abnormal |

| Vegetation needs pruning | The relative efficiency of the converter is abnormal |

| frequency deviation | Converter data integrity | Inverter wakes up late |

|---|---|---|

| Abnormal temperature coefficient | Converter Clipping | Converter failure |

| Device disconnection | Voltage deviation | Abnormal power factor |

| Solar Meter Data Integrity | Tandem power generation performance | Abnormal temperature alarm |

| Environmental sensor failure | Tandem Generation Data Integrity | Converter/AC meter power generation ratio |

| Environmental Sensor Data Consistency | MPPT exception | Transformer is inefficient |

| Solar module clean/dirty | Converter efficiency below specification | Transformer temperature is abnormal |

| Vegetation needs pruning | The relative efficiency of the converter is abnormal |