Intelligent Energy Transformation with Safety and Localization

Support the stabilization of renewable energy power generation to ensure power supply quality, and provide emergency backup power, equipped with disaster prevention functions. It is suitable for frequency regulation, peak load shaving, and the applications of smoothing renewable energy.

Billion Watts Energy Storage System Features

Billion Watts has been deeply involved in the field of solar photovoltaic for many years and deployed localized solutions for energy storage systems to help enterprises achieve energy transformation goals. With innovative technology and customized service, we always adhere to industry-leading quality and gain an advantage in product safety. Providing the longest OEM warranty period in the industry and establishing a close and long-term strategic partnership with customers are also the main reasons for the trust of customers.

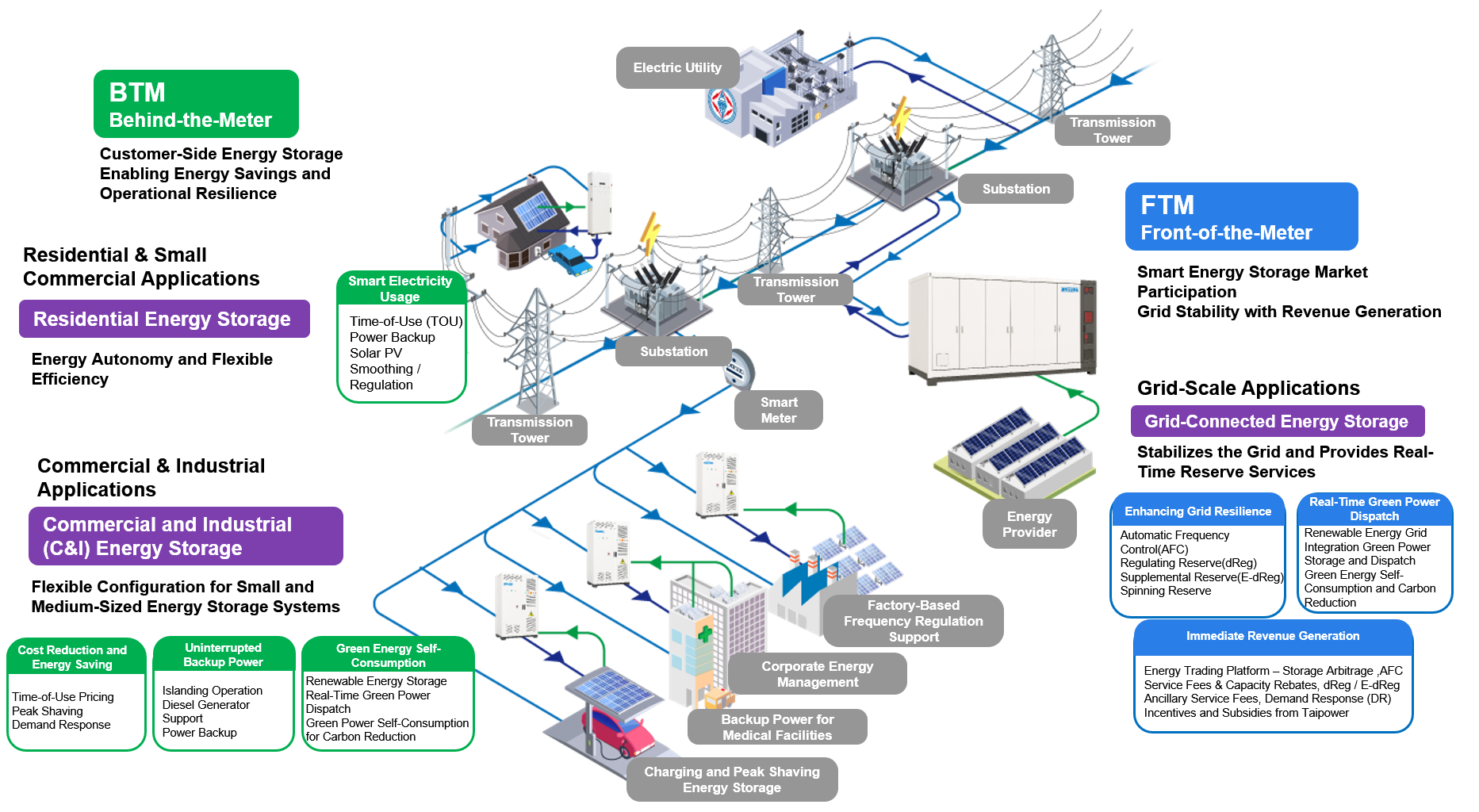

Energy Storage Market Structure and Application Scenarios

Energy Storage System Solutions for Different Fields

ESS of Transmission and Distribution Power Grid-Connected

• Renewable energy smoothing application

• Power type frequency regulation

• AFC Regulation and Frequency Response Service

• Disaster emergency backup power supply

ESS for Compulsory User of Renewable Energy

• Instant contract capacity suppression

• Demand Response

• Energy-based peak load shaving and valley filling

• Solar energy for self-use

• Factory backup power

Solar Plus Storage System Combination for Distributed Energy

• Improve the solar energy utilization rate of the factory

• Factory backup power

• Energy-based peak load shaving and valley filling

• Solar energy for self-use

• Solar energy smoothing

ESS Construction Processes

1. Case Preparation

Location Scouting, landowner lease, application for Taipower feeder, preparation and application for system impact, etc.

2. Energy Storage System Design and Planning

Owner contract execution, electrical and civil engineer drawing, project manager assignment, panel and main equipment procurement, etc.

3. Civil Engineering Construction

layout, weeding and land grading, site excavation, grounding system and piping works, RC foundation in equipment area, etc.

4. System Engineering and Testing

Weak current and high voltage power system engineering, EMS network monitoring system engineering, equipment positioning, testing before power transmission, etc.

5. Cooperate with Relevant Unit for The Final Acceptance

Acceptance of test items, system start-up test, acceptance of related data , Taipower transmission, education and training, etc.

6. O&M Team Takes Over

After-sales service, follow-up maintenance service of the case site, spare parts procurement and replacement operations, etc.

Energy Storage Battery Container System Feature

- The battery is made of cutting-edge materials and possesses the advantage of high energy density, lightweight, high efficiency of heat dissipation and safety.

- Suitable for power type frequency regulation, energy peak load shaving, and renewable energy smoothing.

- Comply with the dReg 0.25/dReg 0.5/E-dReg commodity specifications of Regulation and Frequency Response Ancillary Service.

- Installation capacity:2.5MWh-5MWh / 20ft container.

- Warranty and maintenance:deeply involved in localized operator and provide 15-year warranty for battery with 15-20-year life and keep SOH 80% above.

Safety Instructions

Product and Service

ESS Battery and BMS

Cell/Module/Rack

The cell adopts a high-energy lithium-ion battery, which possesses a high energy density. Its volume/energy ratio and weight/energy ratio are both high. The cycle life can be used for more than 6000-8000 cycles. The battery also possesses low internal resistance and fewer overheating problems with 5/10/15-year warranty with useful life up to 20 years.

PCS

Flexibly collocate with the operation and grid-connected mode

We provide PCS and battery combinations made in Taiwan to choose and combine. PCS complies with IEC62477 and UL1741 specifications, supports Modbus-RTU/ Modbus-TCP/ IEC 61850-RS485 communication protocols, etc. With DC/AC conversion efficiency up to 98% and 5/10-year warranty.

- 500kW - 750kW

- 1MW - 1.5MW

- 2MW - 2.8MW

- 3MW - 4.3MW

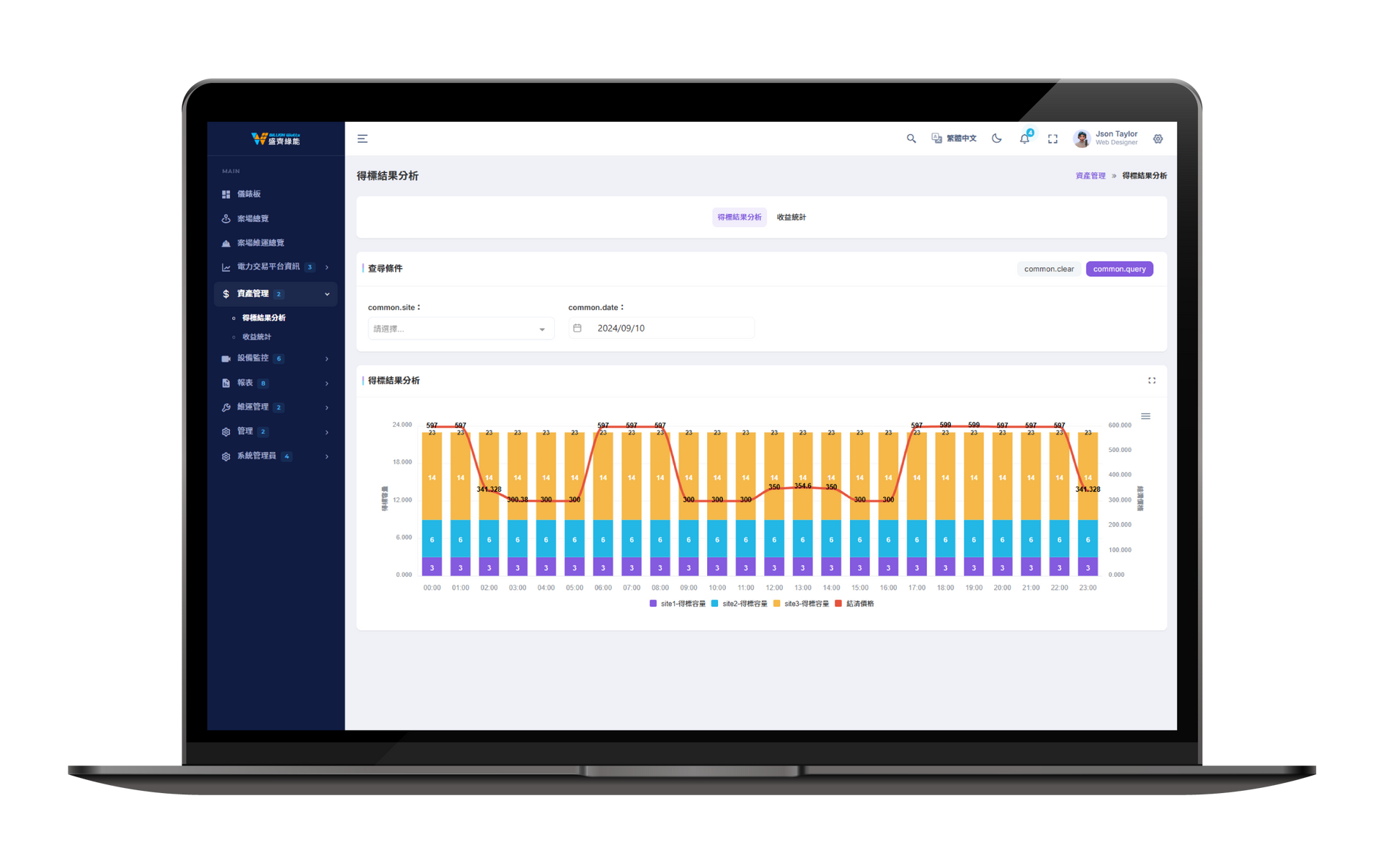

ESS 5.0

Real-time operation information and alarm event record

• Multi-site cloud integration with one-stop login for real-time monitoring

• Real-time display of power generation and consumption, with clear operational status

• Automatic alarm notifications for rapid reporting of abnormal events

• Support for historical data and trend analysis to optimize operational decisions

• API integration with Taipower and internal enterprise platforms

EPC

Engineering, Procurement, Construction

Including project management and design, power interfacing (distribution boards, transformers), civil engineering construction, integrated communication testing and O&M services.

Agent for Aggregation Service

Professional operation by qualified traders

Using TPC regulation reserve data and reference of various power generation resource data which are publicly available, traders accurately make judgement and decision for bidding price, and intuitively operate to achieve quick filling-in-form and bidding. Each resource revenue status on the dashboard is obvious at a glance, which ensures execution with efficiency and system availability.

Energy Storage Insurance Service

Main risks in the construction/operation phase of energy storage stations

• Hoisting collision and falling

• Fire/explosion

• Third-party liability: fire spread and pollution

• Loss of operation revenue

• Battery performance degradation and warranty risks

(Uninsurable Risk)

Why choose Billion Watts' solution?

To build a one-stop renewable energy as a service (EaaS) company in Asia.

Provide a one-stop service for the integration of MW-level smart energy storage system containers and monitoring systems.

Provide power distribution and transmission grade grid-connected energy storage, large electricity consumers, behind-the-meter energy storage, photovoltaic combined energy storage and other solutions.

Taipower AFC power trading platform bidding on behalf of client and maintenance services.

Energy Storage Maintenance Service

Billion Watts focuses on, from the integration of battery, BMS, PCS, EMS to monitoring and O&M and also develops the energy storage business through one-stop. The O&M team provides energy storage system design and planning, construction and machine adjustment, operation and maintenance. Our staff has relevant certificates:

- Class A electrician / Class B Solar photovoltaic installation technician

- Safety and hygiene certificate for supervisor of labor safety and hygiene affairs

- Safety and hygiene certificate for roof work supervisor

- First responder safety and health certificate/Taiwan occupational safety card

Billion Electric Yilan Energy Storage Container Assembly Factory

- Cooperate with major international manufacturers to properly deploy the integration of key components and electromechanical systems in the energy storage industry chain.

- Localize the manufacturing technique of energy storage container (with full traceability), including cell characteristic measurement grouping, energy storage battery module assembly, battery module welding, and energy storage battery container assembly.

- Ship batteries and containers to Taiwan for system integration power interfacing engineering, such as local assembly, calibration and testing, etc. There are enough batteries and peripheral spare parts in stock.

- Provide immediate backup machine replacement and repair during the warranty period of energy storage system to reduce the repair time resulting in operating interruption and failure risk.

I have lands in an industrial area for rental

If you have idle land in an industrial area, you can rent it out to us to set up an additional energy storage plant. The landlords don’t have to bear the construction cost and can earn stable rentals as a return from it. Billion Watts provides consulting services and professional on-site evaluation. Please fill in your inquiry information, we will have someone contact you, or call 0800-585-665.